DOE without the math: Synthace calculates stock solutions for you

No scientist I know enjoys the trial and error involved with finding the right number, and concentration, of stocks.

Like so many tasks in biology, it can make you suffer from a kind of “Goldilocks Syndrome”. You shift your focus away from your experiment – and you obsess over making sure that your stock liquids are, as the curious blonde in The Three Bears puts it, “just right”.

Small enough to fit in the final total volume, at the specified final concentration. But large enough to pipette accurately.

This “Goldilocks Syndrome” starts to become particularly problematic when you’re planning a complex Design of Experiments (DOE) design.

Why stock solution calculations and complex DOEs don't mix

Calculating the stock concentrations for a (somewhat) simple DOE might just be doable. You could only need one stock for your design. And after a few tries, you’ll likely find a concentration that’s “just right”. No sweat.

But doing that kind of math at scale – a DOE spanning a wide range of end point concentrations – can become a real bottleneck.

At that point, you might be calculating solutions to satisfy tens, or even hundreds, of runs. You might have 10 different liquids going into any single well, and each well probably needs to hold different concentrations of each liquid.

And of course, every time you change the concentration stocks of one of your liquids, it’ll likely have a knock-on effect on the rest. Plus, every change to your DOE design in the planning stage can alter set point values.

Getting to “just right” with a DOE’s added complexity becomes an all-consuming distraction from the science – a vicious cycle of calculating (and recalculating) stock concentrations for each liquid.

Back when I was planning my first complex DOE, I remember having no idea where to start.

I wasted hours figuring out the best way to do the math. I tried to come up with clever spreadsheets – as no online stock solutions calculator that I found was much use. It helped remove some of the basic mental math, but it couldn’t give me an optimal solution on a platter.

Synthace automatically calculates the optimal stock concentrations for you

Now, thanks to the launch of the latest edition of Synthace DOE, we’ve created something to do just that.

We know first hand that DOE is complex enough without this extra burden in the planning process. We were determined to strip the DOE process of all the things that no scientist should have to worry about – and instead focus on parts that we, as scientists, do best.

Here, that meant removing the math – the messy trial and error involved in calculating stocks entirely.

From now on, no scientist with a Synthace license will ever have to calculate how many stock liquids they’ll need, and what their concentrations are.

Synthace DOE automatically calculates – and adjusts – the optimal ones for you.

Calculating stock concentrations with Synthace: What you need to know

Curious to learn more about how Synthace removes the math from the stock solutions equation? Let’s dive in:

How do I calculate the optimal concentration of stocks with Synthace?

You won’t need to calculate a thing. Synthace will automatically determine the correct stock concentrations that you’ll need for each liquid.

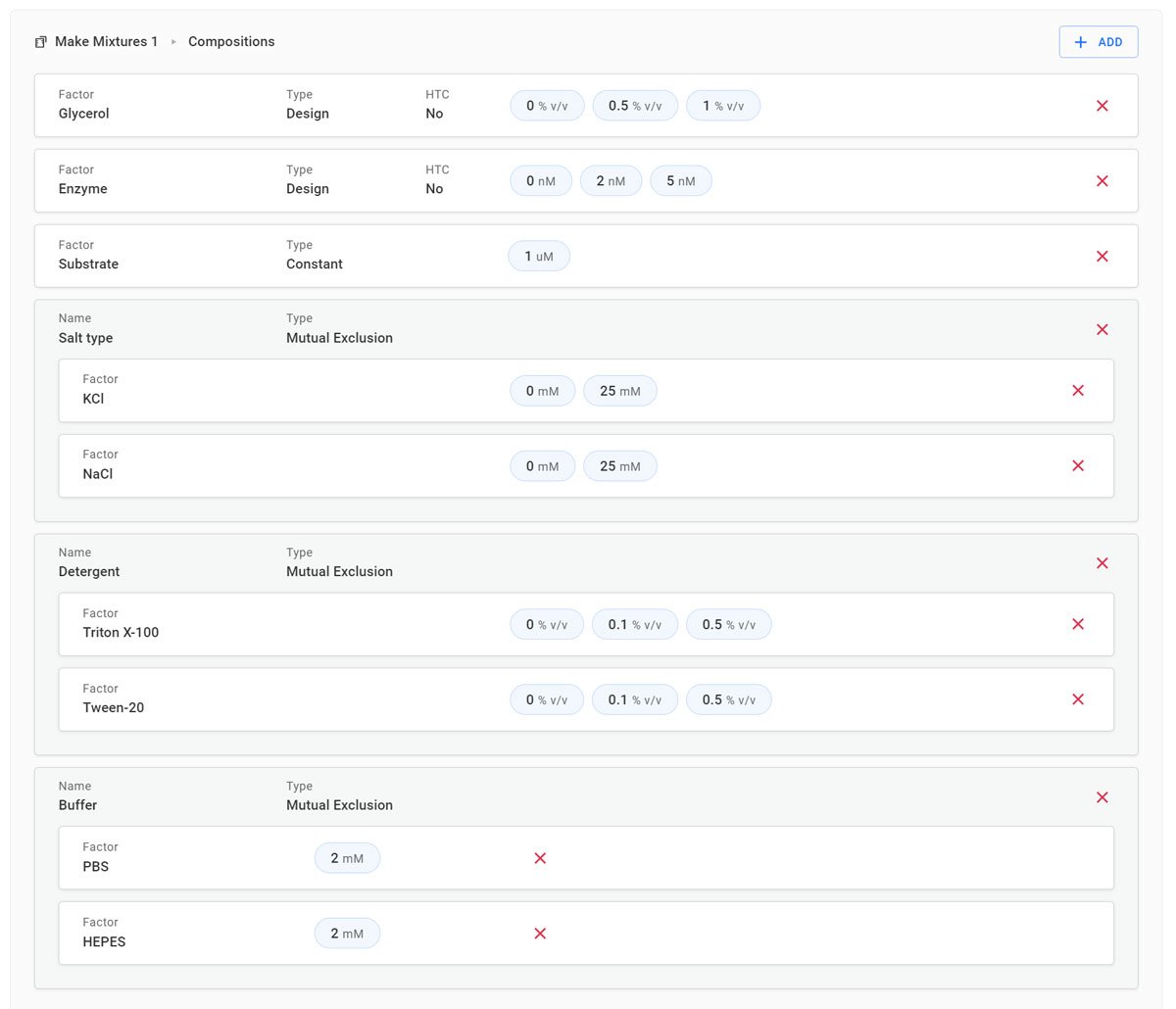

All you need to provide is:

- The factor levels

- The final total volume

- The minimum transfer volume that the device can (or that you’d trust yourself to) pipette

- The maximum concentration at which you can prepare each liquid

Can I limit the number of stocks that I'm willing to make?

No one has the patience to create 16 different stocks for any one liquid – or infinite bench space to store them. Which is why Synthace also allows you to determine the maximum number of stock liquids that you're willing to prepare, per liquid.

What happens if I change my design?

DOE is an iterative process – and there’s any change to the design, Synthace uses the information that you’ve provided to automatically recalculate the “optimal” stocks for your new design.

You can then confirm that the right end point concentrations are met by using the preview.

Synthace in action: Calculating stocks for a complex assay development DOE

All sounds great in theory, but it's always easier to explain with a practical example.

The experiment

Imagine that you’re preparing an enzymatic assay.

And it’s a fairly complicated design. All in all, you’re looking at 384 runs.

In any given well, you’d be adding glycerol, the enzyme, a substrate, plus one of the two listed types of salts, detergents, and buffers. That adds up to 6 liquids going into each well – and all six liquids will be at different concentrations, so they’ll all need different volumes.

You’d start by adding all the details of your liquids into Synthace.

The problematic math involved

Without Synthace, you’d have to calculate concentrations for 9 different liquids, across a wide range of concentration end points. And some of those concentration end points have different units.

Synthace's solution

What might have taken you hours of head scratching and recalculating, will take Synthace no time at all.

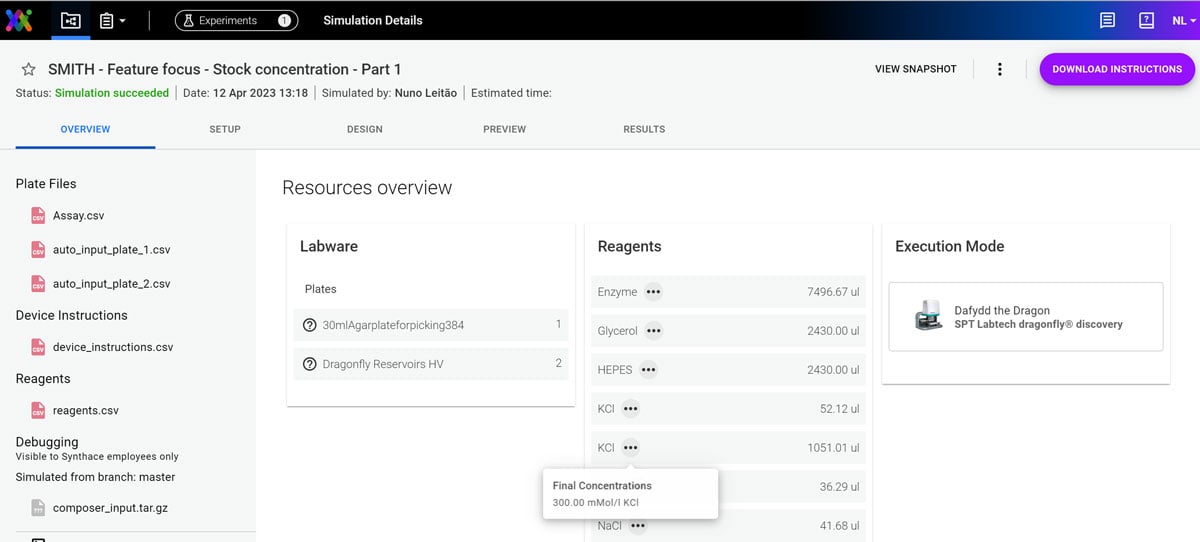

Based on the details that you provide, Synthace’s “Resources overview” section will tell you how many different stock concentrations of the same liquids you’d need to make to satisfy your design:

- NaCl (5 mM, 50 mM and 5M)

- KCl (30 mM and 300 mM)

- Triton X-100 (5%, 0.5% and 0.05%)

- Tween-20 (5%, 0.5% and 0.05%)

Synthace will also tell you when a single stock is enough:

- Enzyme (15 nM)

- Glycerol (10%)

- HEPES (20 mM)

- PBS (20 mM)

- Substrate (10 uM)

Now, you're ready to move on to doing the experiment! No muss. No fuss. And an awful lot of time saved.

Want to learn more about Synthace DOE?

Try taking an interactive product tour. And to see how Synthace’s DOE workflow could cut time to insight in your lab, our team are here to help – arrange a demo today.

Nuno Leitão, PhD

Dr. Nuno Leitão is a Principal Research Scientist at Synthace, where he leverages his 10 years of research experience in molecular biology, genetics, biochemistry, and DOE, to help drive product development. In his 5 years at the company, he has led and consulted on many internal projects and customer initiatives.