Liquid Handling Robot Performance Monitoring – Why is it important?

Imagine you’re running large screening experimental campaigns on automated liquid handlers at a biopharmaceutical company…

Your assays are very expensive, possibly $100 per plate, maybe even more, so there’s clearly no room for error...

Now imagine if two weeks later, your analysis does not make sense, and you can’t figure out why. After triple-checking all your methods and equipment, you realize the errors were down to the poor liquid handling performance…

What is Liquid Handling Robot Performance Monitoring? Why does it matter?

So what is liquid handling robot performance monitoring? It is scientists monitoring their devices frequently enough to ensure and be confident that their liquid handling equipment is consistently transferring the right volumes for their assay and for scientists to immediately know that failures were not down to device specification drift.

To benefit from recent technological advances, life science laboratories around the world have been adopting high-precision automated liquid handling robots to increase the throughput and reproducibility of a wide range of assays. This widespread implementation heavily contributes to significant advances in our understanding of science and medicine. Experiments that will really benefit with these advances are assays such as the Enzyme-Linked ImmunoSorbent Assay (ELISA), protein detection such as the Bradford assay or the Anti-Drug Antibody assays (ADA) for the understanding of antibodies that bind to proteins of interest. However, speed and automation do not guarantee accurate results. Experiments are dependent on reagent concentrations and these differ by different volume dispenses. If a liquid handler is inaccurate in the volumes it dispenses, then the experiment will be highly impacted and possibly deemed unreliable jeopardizing the entire experimental campaign.

There are a wide range of high-precision liquid handling robots but the most common ones are the Hamilton Microlab STAR liquid handler and the Tecan liquid handlers - Freedom EVO or the Tecan Fluent. When a brand new shiny liquid handler arrives on site, it is verified by the vendors with an Installation Qualification (IQ), an Operational Qualification (OQ) and a Performance Qualification (PQ). Once ready a maintenance contract is usually signed which provides a performance check once or twice a year.

But the main problem here is that these checks are too infrequent. Device specification drift can happen. Imagine you run your Tecan Freedom EVOware automated liquid handler 3 times a week, that’s 156 times a year but you only check if it's aspirating and dispensing correctly twice. Out of those 156 experiments, how many times did the experiment fail due to liquid handling inaccuracy, when did it fail, and why. Instead of quickly iterating through experiments scientists have to dedicate time troubleshooting why their experiments failed.

How do you Monitor your Liquid Handling Robot Performance?

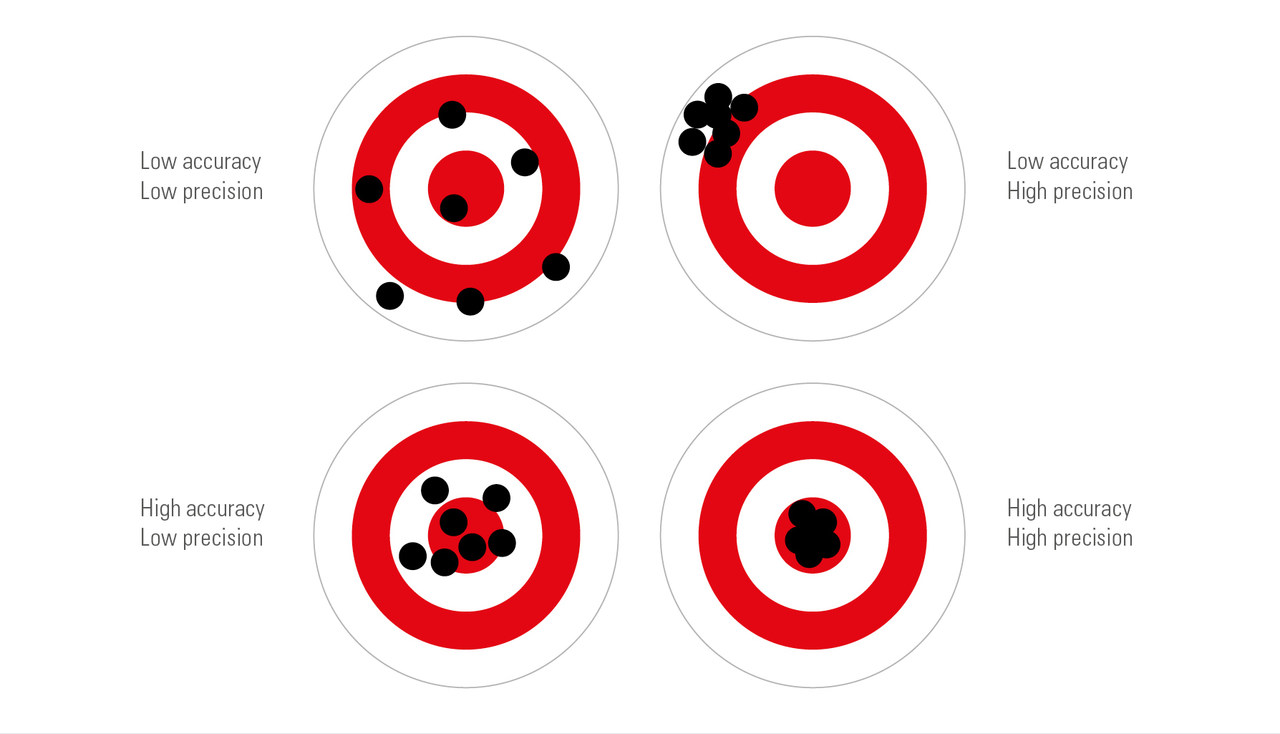

A liquid handling device is our power tool and has one simple goal. It should reproducibly deliver the target volume with high accuracy and precision. It should also have consistent and predictable behavior according to the methods the user has programmed. Scientists need to monitor and control their liquid handlers to ensure it is reaching target volumes accurately and precisely. Not knowing this vital information will cause uncertainty to your experiments and ultimately waste crucial reagents.

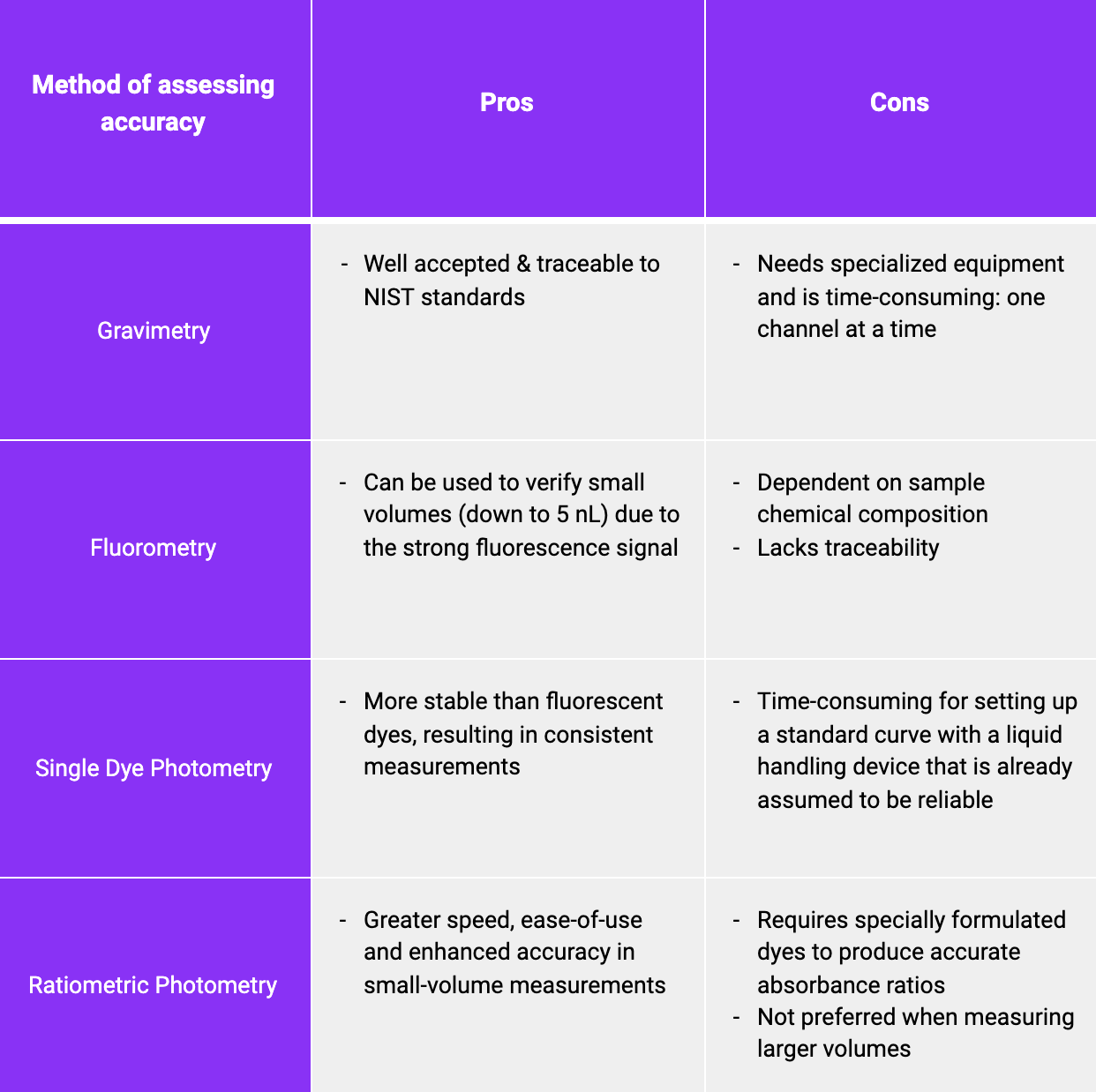

There are a few common ways to test the accuracy and precision of your liquid handling device that scientists can use. They are outlined in the table below with the pros and cons of each. The focus here is not to discuss the advantages or disadvantages of any method, but just highlight them. The most important aspect is to have a robust method for proper volume verification applicable to the type of experiments the laboratory will mostly be running.

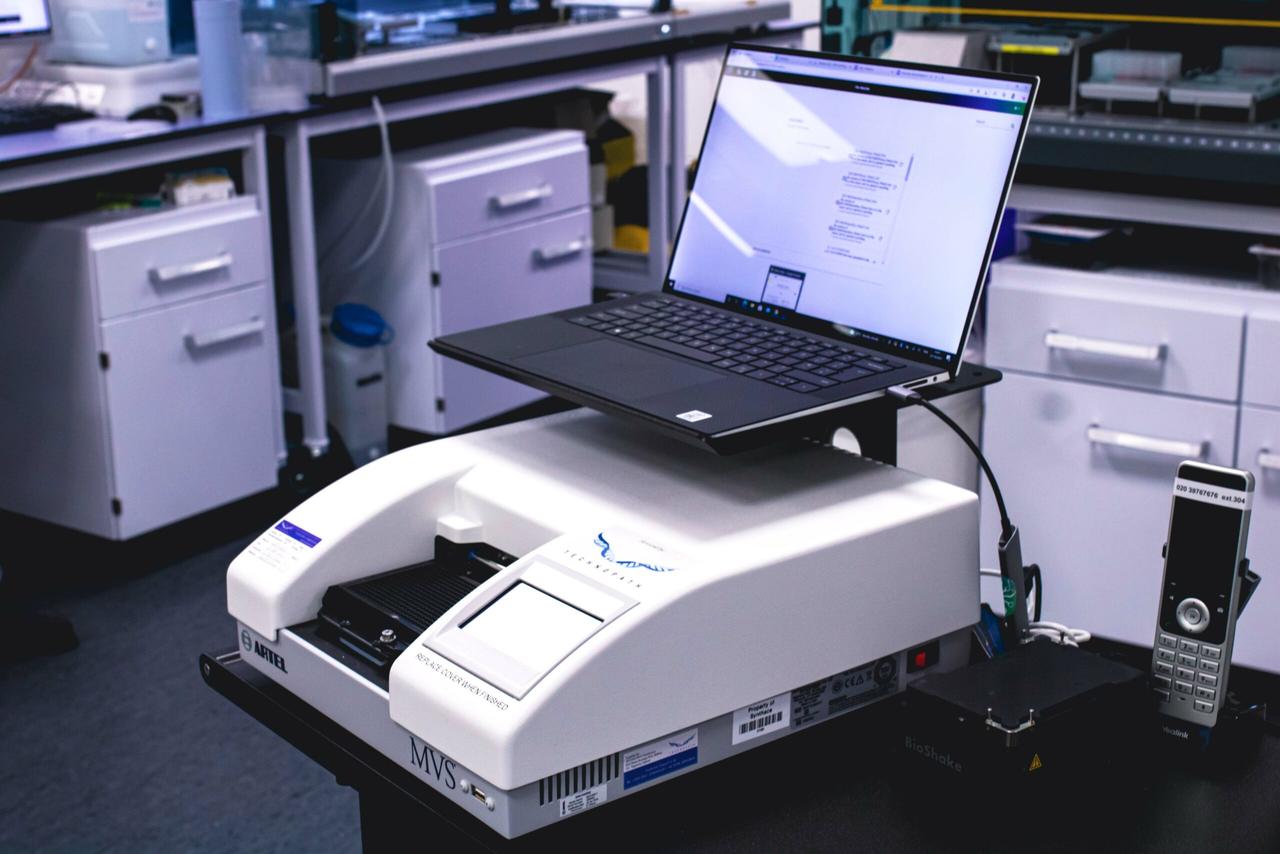

An example here is if your lab mostly runs quantitative Polymerase Chain Reaction (qPCR), then you should employ a method that verifies low-volume transfers. One such method that will be very beneficial for low-volume transfers is the Artel MVS Multichannel Verification System. It is compatible with any liquid handling system such as the Hamilton automated liquid handling platforms and the Tecan liquid handling systems.

After reading this, will you Monitor your Automated Liquid Handling Robot for Accuracy and Precision?

Regardless of the frequency between maintenance checks, it is important to have a process in place to be used for interim checks to know exactly how your automated liquid handling robot is performing over time.

Performing frequent checks will also allow the user to have confidence in their methods and results as well as avoid the loss of rare expensive reagents. Before you begin an experiment important questions may be asked about the liquid handler.

- Is the performance of the liquid handler of choice applicable for the planned experiment?

- Does the device need to be calibrated and subsequently validated?

- What is the desired volume range?

- If the target volume is not exact, is it better to under dispense or over dispense?

- What are the assay's experimental tolerances?

It is important to note that these and other questions may be asked and should be critically evaluated. Alongside this there are many factors that can affect liquid handling accuracy and precision and it is important to understand how these may affect the performance so that we can anticipate the outcomes of our experiment. These factors below are the most common but it is not limited to other factors such as the environment.

- Volume of liquid

- Plate type

- Tip type

- Filter tips/non-filter

- Liquid type

- Dry contact dispense / wet dispense / free dispense

- Liquid class settings - aspirate/dispense speeds, blow-out, liquid level detection, etc.

- Tip reuse

While automated liquid handling robots have improved efficiency and productivity, the promised increases in efficiency will only be true when the volumes they dispense match the requirements of the application the scientist requires. Liquid handlers can be inaccurate, but regular checks can help scientists understand the tolerances of their liquid handler and provide them confidence in running their experiments.

If you are trying to improve your liquid handling performance then a systematic and efficient method that enables scientists to study the interactions between factors impacting liquid handling is the use of Design of Experiments (DOE). Feel free to contact us and our scientific solutions consultant will be happy to have an exploratory call.